EPP Shape Machine: From Beads to Durable Products

EPP Shape Machine: From Beads to Durable Products

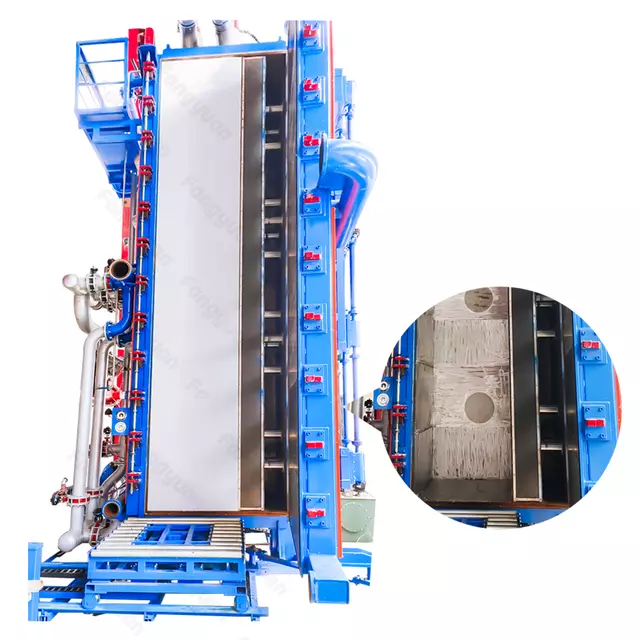

The EPP Shape Machine takes raw expanded polypropylene (EPP) beads and transforms them into durable, lightweight products. Through a precise process involving heating, injection, and cooling, the machine molds EPP beads into specific shapes for a wide range of applications.

In the first stage, the machine heats the beads, expanding them and making them moldable. Once they reach the right consistency, they are injected into a mold. After cooling, the molded product becomes solid and ready for use. The versatility of the EPP Shape Machine makes it a valuable tool in industries like packaging, automotive, and construction.

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

EPP Shape Machine: Precision Technology for Versatile MoldingOct,27,2024

EPP Shape Machine: Precision Technology for Versatile MoldingOct,27,2024 -

Energy-Saving EPS Machine for Versatile Moulding NeedsNov,10,2024

Energy-Saving EPS Machine for Versatile Moulding NeedsNov,10,2024

Links

Links