Molding Custom EPP Products with the EPP Shape Machine

Oct,27,2024visited: 156

Molding Custom EPP Products with the EPP Shape Machine

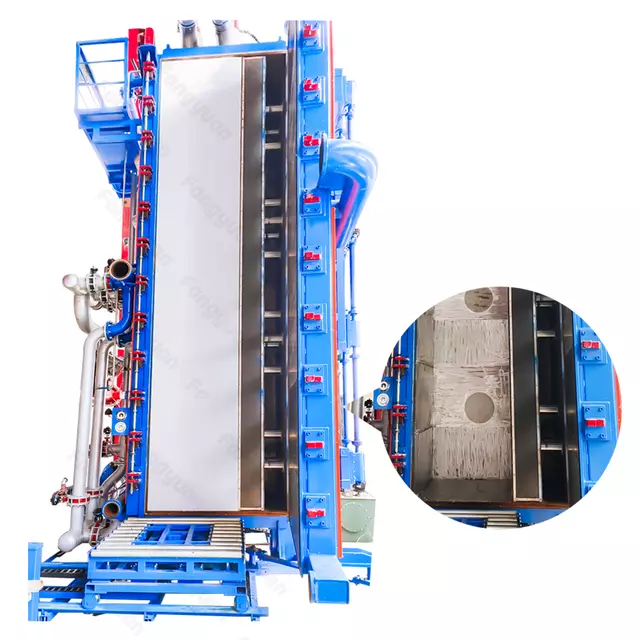

The EPP Shape Machine is at the heart of molding custom parts from expanded polypropylene (EPP). This machine uses a precise combination of heating, injection, and cooling to shape EPP beads into highly durable and lightweight products.

The process begins by heating the beads, which causes them to expand. Once expanded, they are injected into a mold that gives them their shape. After a quick cooling phase, the molded product is ready to be used. This machine is a key asset in industries that require strong, lightweight materials like EPP.

Molding Custom EPP Products with the EPP Shape Machine

end

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

EPP Shape Machine: Precision Technology for Versatile MoldingOct,27,2024

EPP Shape Machine: Precision Technology for Versatile MoldingOct,27,2024 -

Energy-Saving EPS Machine for Versatile Moulding NeedsNov,10,2024

Energy-Saving EPS Machine for Versatile Moulding NeedsNov,10,2024

Links

Links