EPP Shape Machine: Shaping the Future of Lightweight Manufacturing

EPP Shape Machine: Shaping the Future of Lightweight Manufacturing

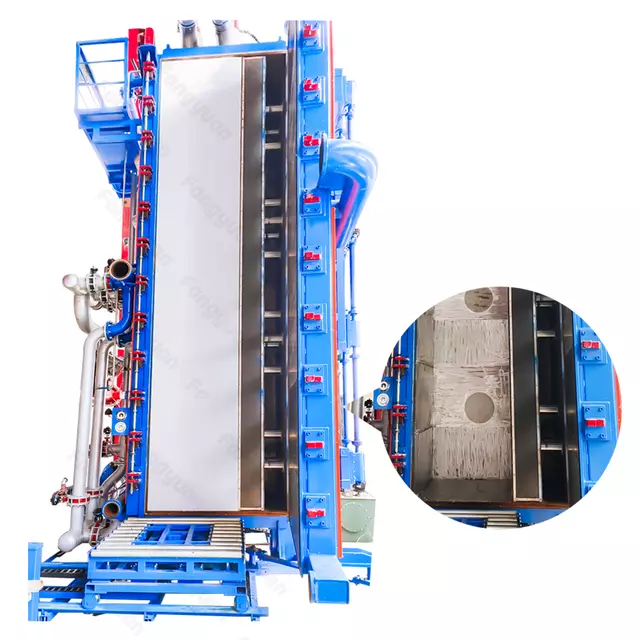

The EPP Shape Machine plays a vital role in manufacturing by shaping expanded polypropylene (EPP) into lightweight and durable products. Through a process that involves heating, injecting, and cooling, this machine creates custom-molded parts that are ideal for a variety of applications.

The machine starts by heating EPP beads to expand them. These expanded beads are then injected into a mold to take on a specific shape. After the cooling process, the final product is strong and ready for use. The versatility and efficiency of the EPP Shape Machine make it a key player in modern manufacturing.

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

EPP Shape Machine: Precision Technology for Versatile MoldingOct,27,2024

EPP Shape Machine: Precision Technology for Versatile MoldingOct,27,2024 -

Energy-Saving EPS Machine for Versatile Moulding NeedsNov,10,2024

Energy-Saving EPS Machine for Versatile Moulding NeedsNov,10,2024

Links

Links